How does a recycling-based DualPore™ Metal Scavenger work?

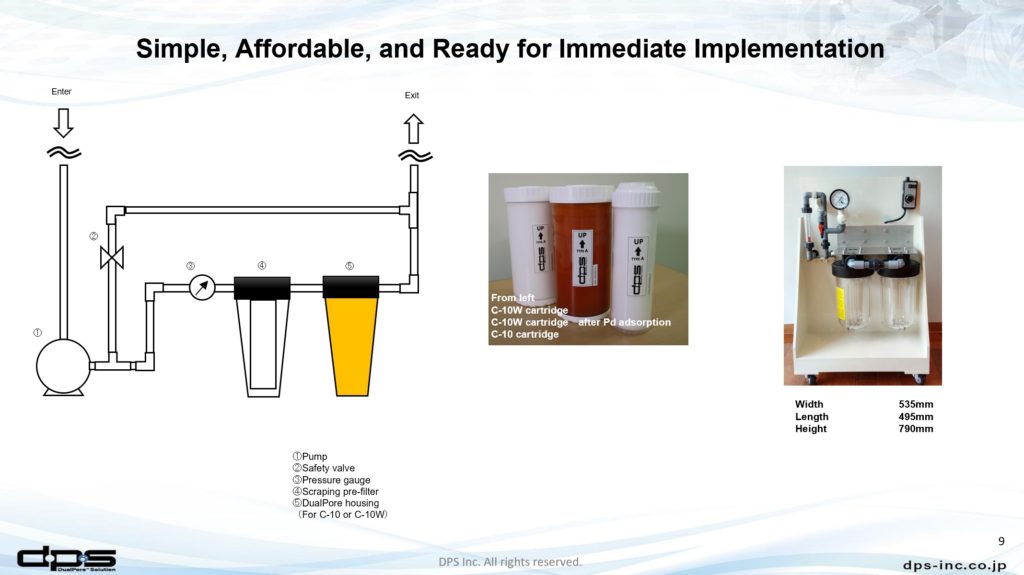

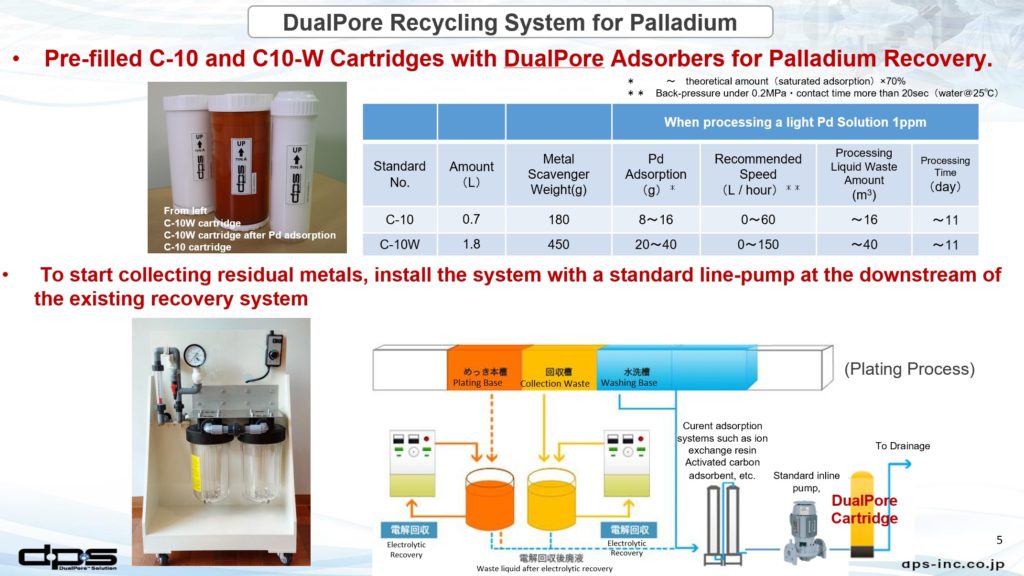

Recycling-based metal scavengers efficiently adsorb and remove residual trace metals from solutions and waste liquids. They come as cartridges prefilled with “DualPore™“ material, ready for immediate use, and can be reused after the adsorbed metals are collected and sold.

With the application of ion exchange or new chelating function surface modification technology to “DualPore™ Silica”, we are exploring ways to recover a wider range of rare metals and making precious metal recovery easier and recyclable.

Rare metals are already being recycled; Where is the potential in further recycling it?

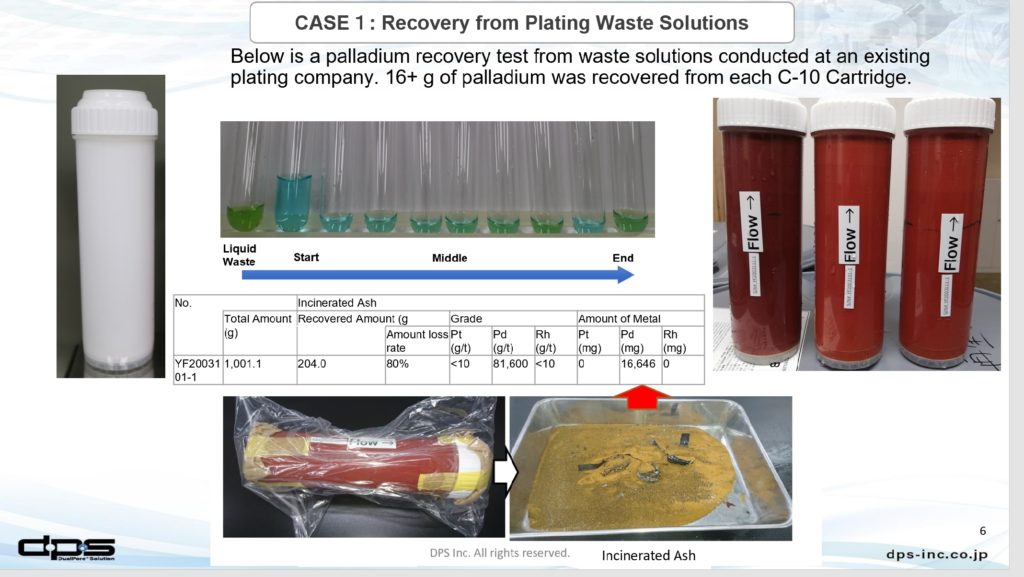

Urban mines are still dormant due to trace concentrations of rare metals in waste liquids. While 1/3 of domestically consumed rare metals including platinum, palladium, and rhodium are indeed being recycled, a larger 2/3 are left uncollected and thrown away, polluting the environment.

Further, metals like palladium are worth equivalent to gold. Recycling these rare metals are not only better for the planet, but offset capital expenses.

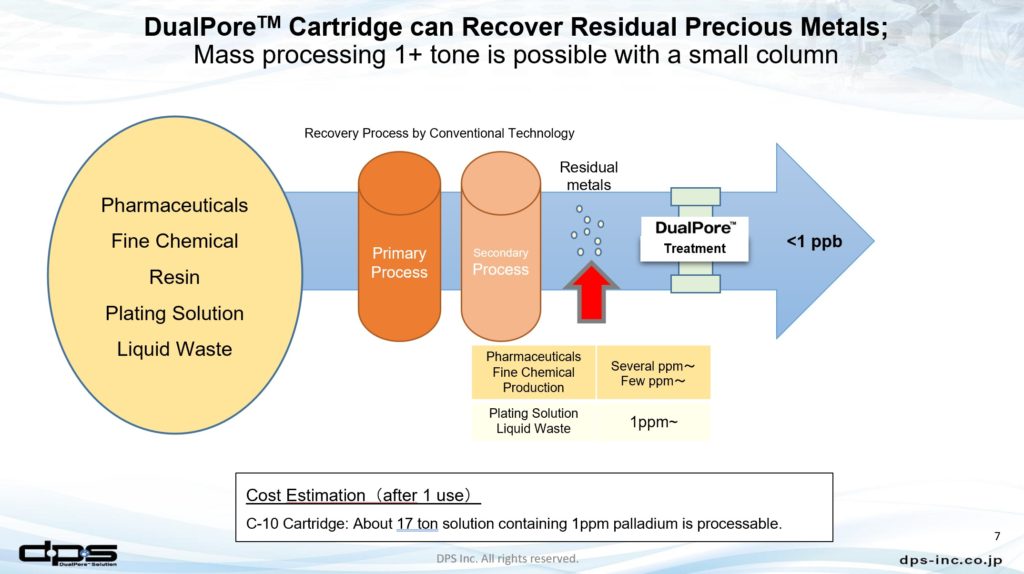

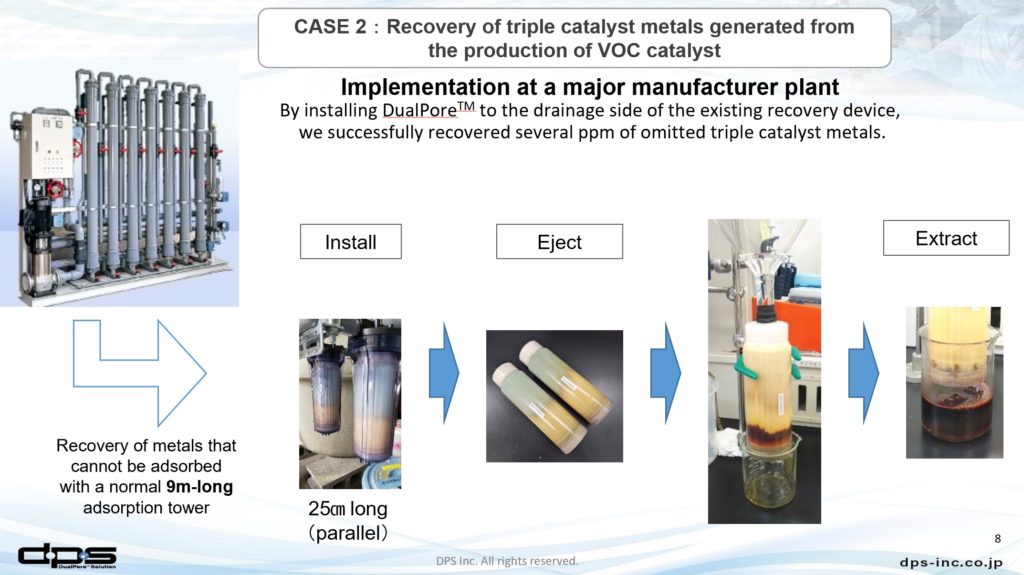

Since our products demonstrate high performance even under low pressures, they can be used with general-purpose cartridges (pipes containing adsorbents that are easy to replace) without the need for expensive high-pressure pumps or equipment. With this, low-concentration precious and rare metals at the level of several ppm (1/1,000,000 concentration), otherwise difficult to recover with conventional technology, can be removed, concentrated, and collected from solutions and waste liquids used in manufacturing processes and production lines (> tons/day) at ~80 times the speed of standard methods.

Precious metals such as gold, palladium, and platinum are used in many products including catalytic metals in automobiles, semiconductors in computers and smartphones, and printed circuit boards in electronic devices. Companies that make such products generate wastewater at the ton level, throwing away trace metals that are otherwise recoverable due to conventionally underdeveloped recovery methods like electrolysis or standard ion-exchange resin.

Put in perspective, a standard 25m pool contains ~ 500 tons of water with a residual palladium concentration of 1ppm. Using DualPore™ metal scavenger, this liquid is concentrated 20,000 times into a 25-liter container in a week, collecting 500 grams of palladium. By refining the recovered cartridge at a recycling company, it is possible to sell the palladium as a concentrated high-grade raw material. Pool water that was worth $0 can now be sold at a market price worth ~$50K using DualPore™.

(After adsorption, we recommend buying another cartridge. However, depending on application, repeated use after elution and recovery of high-purity concentrate is possible.)

We’re looking to partner with businesses handling precious and rare metals.

With the surface modification of DualPore™ Silica using ion exchange or chelating agents, we promote the recovery and recycling of discharged metals from…

– electrical material and semiconductor manufacturers

– plating processing industries

– recycling industries

– electronic device/home appliance manufacturers

– battery manufacturers

– automobile/metal manufacturers

We turn previously unrecoverable metals into profit.

It is possible to recover palladium, whose worth is on par with gold, from solutions with concentrations as low as 0.1 ppm, proven by field studies. Please consider using DualPore™ to your advantage.